In most projects, bending is only half the job.

Depending on the project, the wire often needs to be joined – solidly, accurately and in a way that ensures the whole assembly performs its function.

At Salpark, we perform wire welding and butt welding in-house as an integral stage of manufacturing complete wire components – but also as a standalone service for clients who already have bent parts and need a reliable partner for joining.

We use two proven technologies for joining wire elements:

Each joining method has its place – we select it based on the project’s technical, aesthetic and cost requirements.

Send Your Enquiry

Provide the technical drawing, quantity, material type and preferred joining method (if relevant).

You can send it via the form or by email.

You Confirm – We Proceed

Once the terms are approved, we start production.

We adapt the technology to your project and ensure consistent quality – regardless of the batch size.

Przesyłasz zapytanie

Rysunek techniczny, informacja o ilości, rodzaju materiału i oczekiwanym sposobie łączenia (jeśli to istotne). Możesz to zrobić przez formularz lub mailowo.

Analizujemy i wyceniamy

Sprawdzamy, czy dany element lepiej połączyć metodą TIG czy zgrzewaniem. Jeśli widzimy możliwość uproszczenia lub optymalizacji – dajemy znać. Wycena zazwyczaj wraca do Ciebie w ciągu 1–2 dni roboczych.

We Analyse and Quote

We check whether the element is better joined using TIG welding or butt welding.

If we see opportunities for simplification or optimisation – we’ll let you know.

A quotation usually reaches you within 1–2 working days.

You Receive the Finished Part

or Order More

The welded or joined parts are packed according to your specifications.

You can collect them personally, arrange transport or request courier delivery.

If the result meets your expectations – we continue with further production.

Potwierdzasz – działamy

Po akceptacji warunków przystępujemy do realizacji. Dostosowujemy technologię do projektu i zapewniamy powtarzalność wykonania – niezależnie od serii.

Odbierasz gotowy element

lub zlecasz kolejne serie

Zespawane lub zgrzane elementy pakujemy zgodnie z ustaleniami. Możesz odebrać je osobiście, zlecić transport lub wysyłkę. Jeśli efekt spełnia oczekiwania – kontynuujemy produkcję.

If you have a technical drawing and want to know if we can make it – send it over.

We’ll check it, advise and prepare a quote. No unnecessary waiting and no postponed deadlines.

In wire component production, the joining method greatly affects not only the durability and aesthetics of the component but also cost efficiency, lead time and automation potential.

At Salpark, we use two proven methods: TIG welding and resistance butt welding, selecting the right one based on geometry, material, client expectations and production volume.

TIG (GTAW – Gas Tungsten Arc Welding) is an arc welding process using a non-consumable tungsten electrode in an inert gas shield (usually argon or a mixture of argon with H₂ or He). This method provides full control over the weld pool, resulting in high-quality, visually clean welds – without spatter or the need for grinding when parameters are correct.

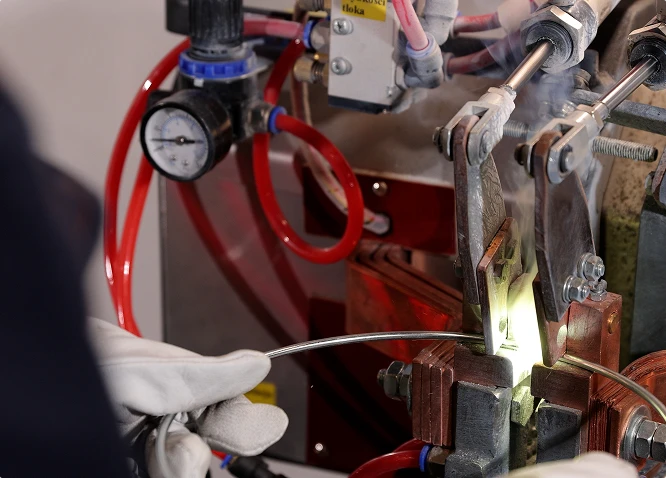

Resistance Butt Welding (RBW) is a method in which two wire ends are pressed together axially while a high-current electrical pulse passes through the joint. The electric energy generates localised heating at the interface until the material softens and fuses.

The result is a strong, clean joint without the need for filler materials.

RBW technology provides extremely clean, consistent and durable joints – ideal where aesthetics, low distortion and automation are important.

It’s the perfect method for mass production of closed wire shapes such as rings, hoops or frames.

At Salpark, every project begins with a thorough technological analysis– to avoid overpaying for TIG where a simple weld will do,, and to prevent using butt welding where a strong, aesthetic joint is required.