At Salpark, we specialise in the production of retaining rings made from spring steel wire, manufactured from round wire with high mechanical strength.

We offer components designed for demanding industrial environments, ensuring dimensional repeatability, production flexibility and the possibility of custom adjustments.

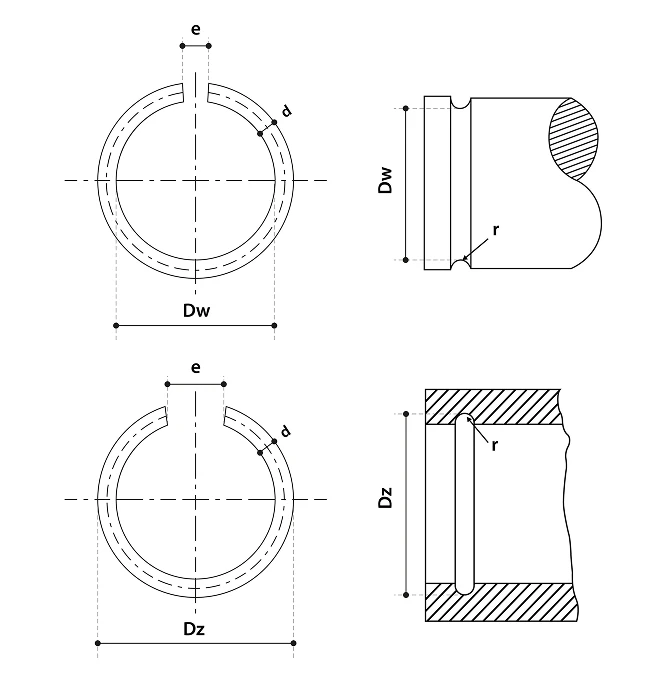

Our retaining rings are used as securing elements in axial applications – for installation in shaft, bushing and guide grooves, as well as in other mechanical assemblies. We produce them in standard warehouse series, based on verified parameters and standards that meet the most common industrial requirements.

Have specific requirements or need rings in a non-standard variant?

Contact us – we’ll check feasibility and prepare an individual quotation.

Our round wire retaining rings are designed and manufactured for real industrial conditions – where resistance to wear, dimensional stability, elasticity and consistent production quality truly matter.

We understand that even small deviations can affect safety, machine reliability and assembly efficiency. That’s why we offer industrial-grade technical components, made from precisely selected materials and compliant with the expectations of the most demanding clients.

Technical Specifications:

Every component is manufactured based on the customer’s documentation or a prepared technical specification, with precision and quality control at every stage.

This ensures that the rings you order are not only dimensionally accurate, but also prepared to operate in specific conditions – without the risk of deformation, corrosion, or assembly issues.

That means fewer downtimes, fewer complaints, and greater peace of mind in daily production.

Wire retaining rings are widely used in:

Their design allows installation without disassembling the entire mechanism, and the spring resilience ensures secure holding even during long-term operation under load.

We understand how important convenience is in further distribution. That’s why we offer the option of packaging retaining rings in single or bulk packaging – as agreed upon with the client.

On request, we can pack products into boxes with labels and partner branding, making them ready for resale or direct integration into production. This is a popular solution among distributors and large manufacturers who want to minimise their logistics time and costs.

We are flexible – we always adapt our shipping methods to your specific order requirements.

Got your own requirements? Let us know.

We’ll adapt – because for us, what matters is that you get exactly what you need.