For over 40 years, we have been supplying components for filter bag mounting systems – including standard snap band rings as well as our proprietary PROSNAP® solution.

Production is carried out in Poland using proven technologies with quality control at every stage.

Our rings are delivered to filter bag manufacturers both domestically and abroad – as part of larger sets or as standalone assembly components.

Our range includes four main types of rings:

Each type is described in the following sections – with a brief overview, advantages, and the function it performs in the filtration system.

PROSNAP™

is a patented retaining ring system developed for filter bag manufacturers, filter unit producers (OEMs), and industrial users seeking a reliable, durable, and easy-to-install solution.

The PROSNAP™ ring eliminates the need for traditional double-cord tapes, textile profiles, or adhesive bands.

Thanks to its specially designed profile, the ring locks mechanically into the filter plate groove, ensuring stability, tightness, and safety during assembly – with no need for sewing it onto the bag.

Key advantages of the PROSNAP™ system:

no need for adhesive or profile tapes,

significantly shorter assembly time and reduced production costs,

stable double-sided sealing – on both the upper and lower plate surfaces,

no need for upper collar profiling,

suitable for high-temperature operation,

reduced risk of incorrect or leaky installation,

recyclable ring – can be disassembled quickly without damaging the filter bag.

PROSNAP™ Ring Construction

This advanced type of ring can be made from tape:

Due to its profile, the PROSNAP™ ring provides exceptional sealing – significantly more effective than traditional SNAP BAND rings, which act mainly on the groove sides.

PROSNAP™ ensures both upper and lower sealing, keeping the filter bag securely in place and maintaining tightness even under intensive use.

Efficiency and Safety

The PROSNAP™ ring is designed with installation safety in mind.

Its slightly larger diameter relative to the housing prevents accidental pushing of the ring into the filter cage, ensuring higher operational safety.

In durability tests, filter bags equipped with the PROSNAP™ ring maintained loads of up to 130 kg without loss of tightness or displacement.

Sewn or Sew-Free?

The PROSNAP™ ring can be used without sewing it onto the filter bag, eliminating the need for stitching along the top seam.

This means:

Additionally, the non-sewn bag design ensures cleaner production processes and better compliance with environmental standards.

The PROSNAP™ system is ideal wherever:

are classic, widely used retaining rings applied in industrial filter bag manufacturing.

They are a proven solution for manufacturers who value dimensional precision, material durability, and operational safety – both during assembly and throughout the filter’s service life.

The rings are made from rolled spring-grade stainless steel strip, offering high chemical and mechanical resistance.

The rolling process produces a smooth, semi-polished surface finish, reducing friction and improving assembly quality.

Each strip is pre-processed to remove sharp edges, which:

The cut strip sections are joined using stainless steel eyelets (rivets), ensuring:

This method guarantees complete material integrity and eliminates the risk of ring degradation when exposed to harsh working environments (e.g., humidity, chemicals, temperature changes).

We can produce Snap Band Rings in almost any diameter – starting from 75 mm, depending on available strip widths and thicknesses.

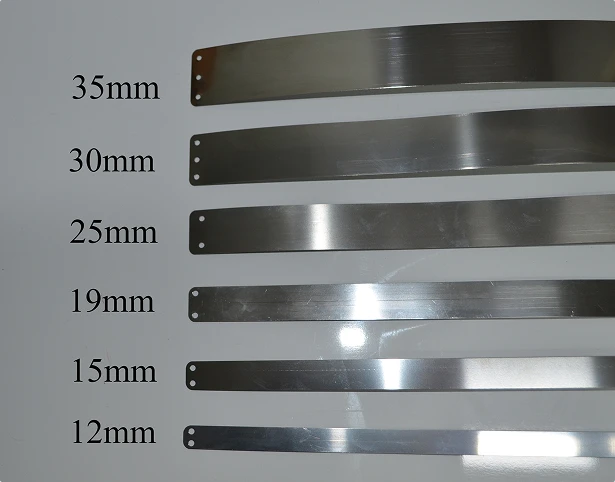

Width / Thickness:

12mm / 0.38mm

15mm / 0.38mm

19mm / 0.38mm

25mm / 0.25mm

25mm / 0.38mm

30mm / 0.38mm

35mm / 0.38mm

12mm / 0.38mm

15mm / 0.38mm

19mm / 0.38mm

25mm / 0.25mm

25mm / 0.38mm

30mm / 0.38mm

35mm / 0.38mm

For applications requiring higher elasticity or strength, we can supply double rings made from two parallel stainless steel strips – an ideal solution for large diameters or filtration systems operating under variable loads.

Upon request, we can customise:

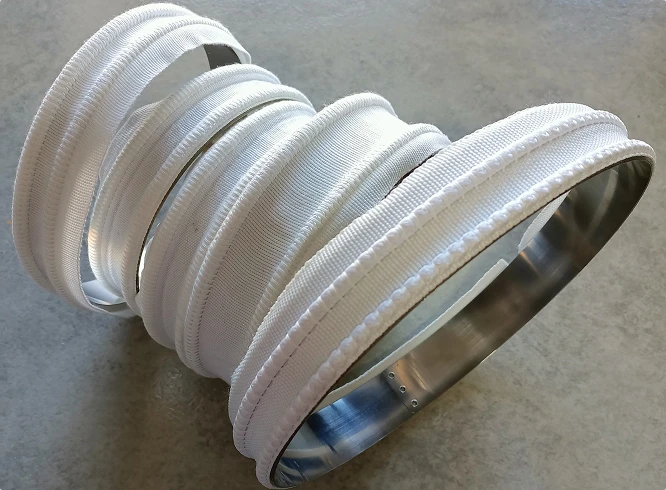

Band Rings with double cord tape are among the most popular and proven solutions in filter bag construction — especially in pulse-jet and reverse-air systems.

Their universality, ease of installation, and sealing effectiveness make them a standard choice in numerous industrial applications.

The ring is made of stainless steel strip, around which a double-cord textile band is formed. These beads provide:

Thanks to their design, double-cord rings eliminate the need for additional seals or adhesives, simplifying both installation and removal of filter bags.

It is worth noting that many filter bag manufacturers apply the beaded band manually — a time-consuming and precision-demanding process.

By outsourcing this process to Salpark, you save time and gain consistent, ready-to-sew constructions without extra assembly steps.

Salpark offers double-cord rings in a variety of sizes and configurations tailored to individual customer requirements.

Standard parameters include:

Rigid wire rings made of steel are components sewn along the length of a filter bag – typically at intervals of several dozen centimetres – to reinforce and stabilize the structure.

While they do not serve a mounting function like retaining rings at the filter plate, they play an important role in ensuring proper bag operation throughout its service life.

The rings are made from steel wire with a specified elasticity, depending on design requirements:

The wire used for production typically has a diameter from 2.5 mm to 6 mm, depending on the bag length and desired structural stiffness.

The rings are bent using modern CNC bending machines with full diameter control.

Depending on requirements, they can be spot-welded or TIG-welded to match the internal diameter of the bag.

They are sewn in during the bag’s manufacturing process or, in the case of repairs and replacements, can be installed later.

Thanks to their design, rigid rings minimize gaps between the bag and support cage, ensuring proper axial alignment during filtration.

In the filtration industry, there is no room for errors. Retaining rings must be consistent, compatible and safe to use — regardless of batch size or the target filtration system.

That is why the production process at Salpark is covered by a certified Quality Management System compliant with PN-EN ISO 9001:2015, issued in the scope of:

„Production of retaining rings for filter bags”.

PL

EN

DE

At Salpark, we have been manufacturing filter bag rings for years – both in classic versions and in patented forms such as PROSNAP™.

We understand there is no room for error in this industry – that’s why every component is produced with strict precision, repeatability, and documentation compliance.

If you need filter bag rings – contact us.

We’ll help you choose the right ring type, adjust its size and material, and prepare a customized variant if needed.

Fill out the contact form – we’ll get back to you with a specific answer.