Some projects require more than a catalogue approach.

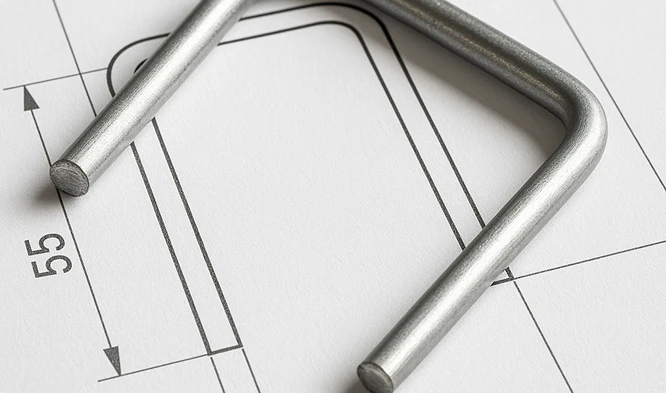

Some parts must be made according to precise technical documentation – accurately, consistently and without guesswork.

At Salpark, we know that clients aren’t just looking for “wire bending” – they need a ready-to-use component that can be immediately fitted into an assembly line, shipped to the customer, or integrated into a system.

That’s why our service doesn’t end with bending.

We perform wire bending using CNC technology (2D and 3D) for diameters from 2 to 12 mm.

At the same time, we offer a range of complementary operations that allow us to complete the entire production process in one place.

We provide end forming, chamfering and threading – according to documentation or customer specifications.

This means you don’t need multiple subcontractors – you order a finished wire component from one company, and we make sure it’s bent, finished and ready for use.

Whether we produce 50 pieces for testing or 5,000 for serial production – the process always looks the same:

Precise, consistent, and complete.

If you have a technical drawing and want to know if we can make it – send it over.

We’ll check it, advise and prepare a quote. No unnecessary waiting and no postponed deadlines.

Wire bending at Salpark isn’t just about CNC machines – it’s about precise parameters you can plan around.

Below you’ll find the exact range of technical capabilities we use every day:

Thanks to CNC-controlled automation, we maintain high repeatability even in short runs.

And if your drawing requires a non-standard approach, we’ll analyse it and suggest a solution – not reject it.

Our CNC wire bending service is used wherever durable, consistent and precisely formed wire elements are required.

We work with both large industrial plants and smaller companies that need short runs for testing, prototyping or production support.

We provide wire bending for, among others:

Each project is handled individually – for us, wire bending at Salpark means not only precise execution, but also real technical support whenever standard methods don’t fit.

Send Your Enquiry

Provide your technical drawing, quantity requirements, material and any notes.

You can do this via the contact form, by e-mail or simply by giving us a call.

We Analyse and Quote

We check if the geometry is feasible within CNC wire bending technology.

If something can be optimised, we’ll let you know. A quotation usually reaches you within 1–2 working days.

You Confirm – We Proceed

Once the terms are approved, we start the process.

We program the CNC machine and complete the order within the agreed timeframe.

You Receive the Finished Part

or Order More

We pack components according to your specifications.

You can collect them personally, arrange transport or request courier delivery.

If the project proves successful – we move on to larger-scale production.

If you have a technical drawing and want to know if we can make it – send it over.

We’ll check it, advise and prepare a quote. No unnecessary waiting and no postponed deadlines.