You need a ready-to-use component – one that doesn’t require running between subcontractors.

That’s exactly what our approach is about.

For many companies, “wire processing” simply means bending. For us, it’s a complete process that can include:

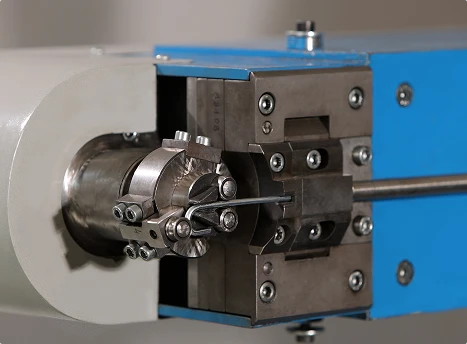

Precise CNC bending in 2D and 3D technology – with additional options such as end forming, threading, chamfering and turning.

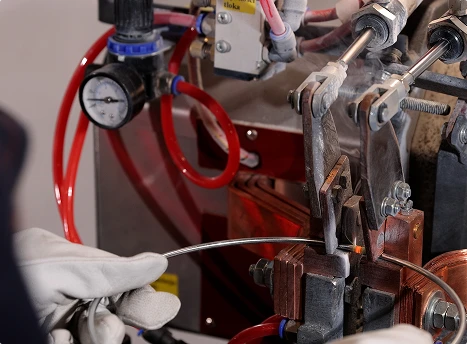

Strong and neat wire connections using TIG welding or butt resistance welding – as part of larger projects or as a standalone service.

We protect components through zinc coating and powder coating – ensuring both durability and aesthetics.

We also handle short runs, prototypes and test projects.

Because we know that the biggest partnerships often start with small projects.

And sometimes the most important thing is… that very first, well-made part.