Standard Stainless Steel Snap band Rings

Composition

Stainless steel snap rings, spring bands and retaining rings are made from stainless steel alloy with unique properties.

The stainless steel strip is rolled to produce a mirror finish. This surface improves corrosion resistance.

Production

At Salpark we put a lot of effort into the process of production. Every snapring for filter bag is carefully handled through each of the stages.

This guarantees that filter bag which includes Salpark’s rings is strong and durable.

The strip is firstly machined to remove the sharp corners. This makes handling safer during sewing into the filter bags. It also protects the filter bag fabric from damage during operation.

The strip is later cut into ring lengths. The lengths are then fastened together using stainless steel eyelets/rivets. The use of stainless steel eyelets eliminates the risk of electrolytic corrosion between the strip and the eyelets. Spot welding can also be performed when required.

Ring dimensions

Rings can be supplied in any diameter size from a minimum of 95mm. Smaller rings can be supplied from some widths of stainless steel strip.

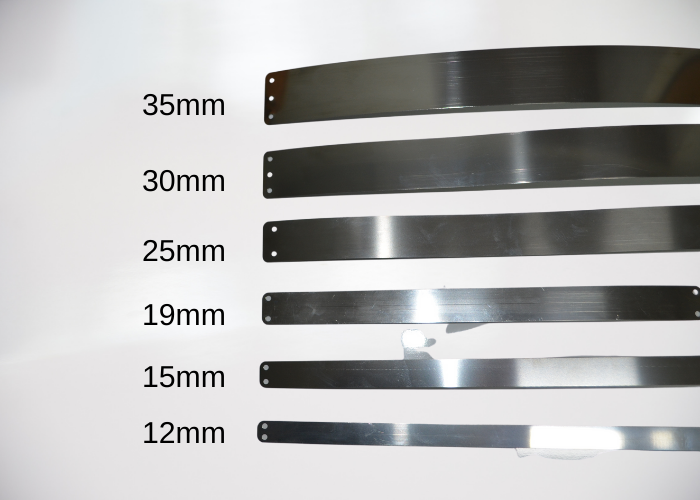

Stainless steel strip dimensions

Stainless steel snap rings can be made from the following sizes of stainless steel strip:

| Width | Thickness |

|---|---|

| 12mm | 0.38mm |

| 15mm | 0.38mm |

| 19mm | 0.38mm |

| 25mm | 0.25mm |

| 25mm | 0.38mm |

| 30mm | 0.38mm |

| 35mm | 0.38mm |

When thicker rings are required we can supply a double ring made from our standard strip sizes. This gives a stronger spring character.

We are happy to discuss enquiries for rings manufactured from other dimensions of stainless steel strip.